Knowledge of book printing technology

Time:2024-11-08

Views:2045

1. Laminating

What is the laminating?

Film lamination is the process of bonding a plastic film coated with adhesive to paper printed materials through heating and pressure, forming a paper plastic integrated product. It is one of the common post press processing techniques for paper printed materials, and commonly used films include matte film, glossy film, scratch resistant film, laser film, tactile film, etc.

Advantage:

1. Products covered with glossy film have a bright and shiny surface, with outstanding visual effects.

2.The surface of the product covered with matte film will not produce reflection.

Disadvantage:

Different types of film covering can affect the final visual effect, such as bright films that may increase reflectivity, while matte films may reduce contrast and color saturation.

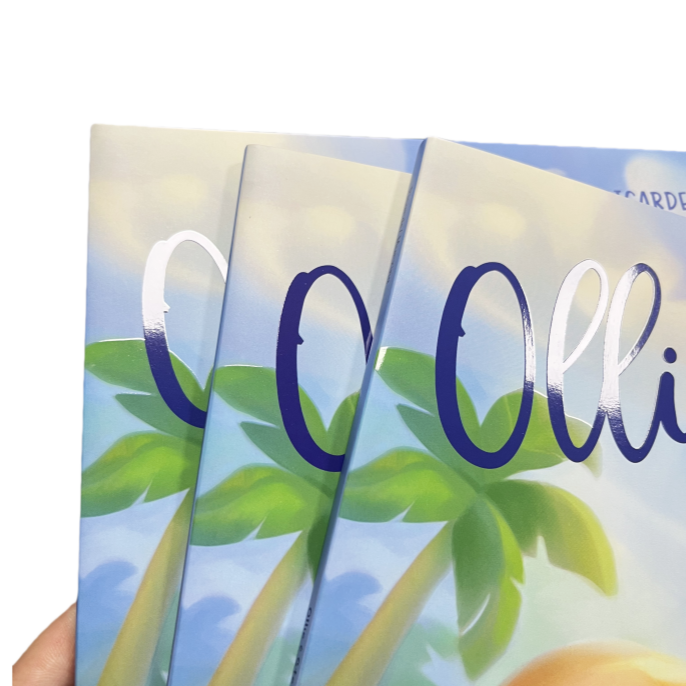

2. Hot stamping/silver stamping

What is hot stamping/silver stamping ?

The hot stamping/silver stamping process is a decorative technique that uses metal foil or silver foil on printed materials. By combining metal foil or silver foil with printed materials through hot pressing, patterns or text can shine in the sunlight.

Hot stamping generally refers to using gold foil for decoration, while silver foil is used for decoration.

Advantage:

1. Hot stamping/silver stamping can give items a more upscale and luxurious appearance

2. Hot stamping/silver foil is usually more durable than ink printing, and is less prone to fading or peeling.

Disadvantage:

Compared to traditional printing methods, the gold/silver hot stamping process has higher costs. The materials used for foil and silver foil are already more expensive than traditional printing materials such as ink, which increases the production cost of the product.

3.UV (partial/full version)

What is UV exposure?

UV printing is generally divided into partial UV and full plate UV. Partial UV is a printing technology that uses ultraviolet light sources to cure coatings on the surface. Full plate UV coats the entire surface of the printed product with a UV coating and is cured by ultraviolet light

Advantage:

Printed products that have undergone partial UV treatment appear more three-dimensional and textured, appearing more vibrant and attractive.

Disadvantage:

UV coatings are usually harder after curing, which may result in insufficient impact resistance in certain specific applications, making them prone to scratches or damage.

Shenzhen Gold Sun Color Printing Factory is a China based book manufacturer, very good at printing hardcover book, photo book, story book, photo album, Printing paper, coloring book, packaging & printing services, Labels, printing stickers, anti-water labels, vinyl label, custom label book , softcover book, custom book printing hardcover, mini book, photobook printing, hardcover book, , board books, color sticker books, sticker books, packaging boxes for small business, custom book, children board books, kids book, journals, notebooks, Agenda, Customs Calendar, magazines, color books, cookbooks, etc. With ISO-2001 and CE certificate, Gold Sun offers very good price and outstanding service.

Welcome contact us through admin@goldsunprinting.com or add whatsapp +86 13802583954. Thank you.