Commonly used binding methods for printed books

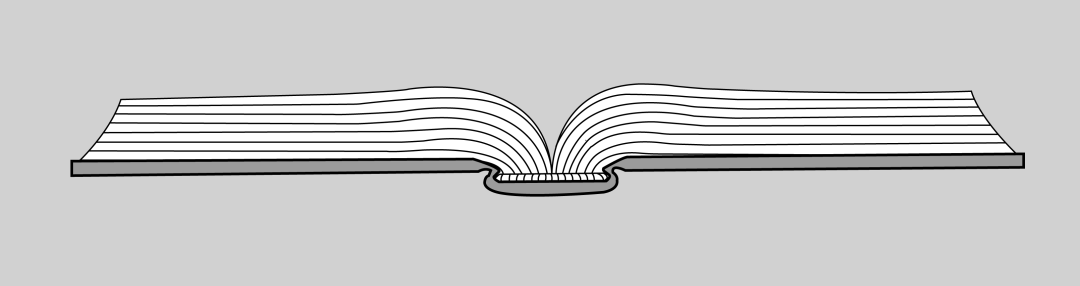

Hard Cover

Product features: Hardbound inner page printed on one side, centered and indented, then mounted in pairs according to the document order, then cut the finished product, and pasted with a plug cloth; After the cover is sprayed and painted, it is pasted onto cardboard and wrapped into a book case. The book block and cover are connected through lining paper to form a book.

Advantages and disadvantages: It is an advanced binding method where the inner pages can be flattened 180 degrees, and the number of inner pages should not be too large, usually below 20p (10 pages). The overall appearance is beautiful and atmospheric, and the entire picture and text are intact.

Equipment used: laser printer, color inkjet printer, laminating machine, and indentation machine.

Applicable scale: Binding of documents with cross page images, such as photo albums, picture albums, brochures, and high-end recipes.

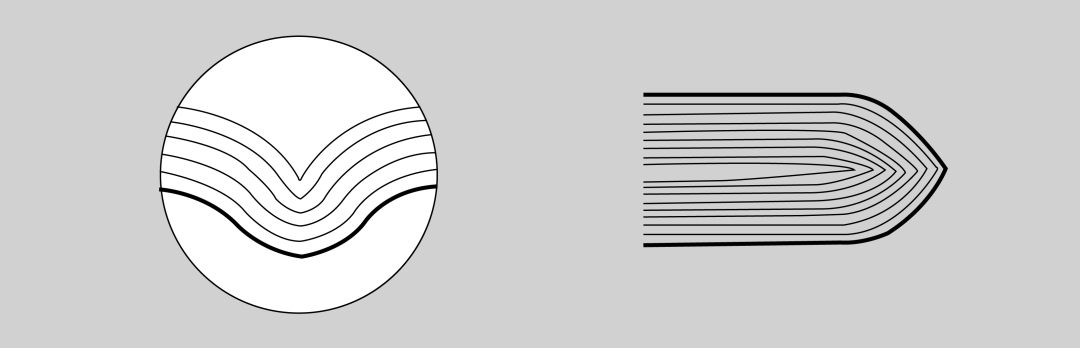

Adhesive locking wire

Main use: For thicker books, in order to increase the firmness of the book‘s inner page binding, it is necessary to lock and reinforce.

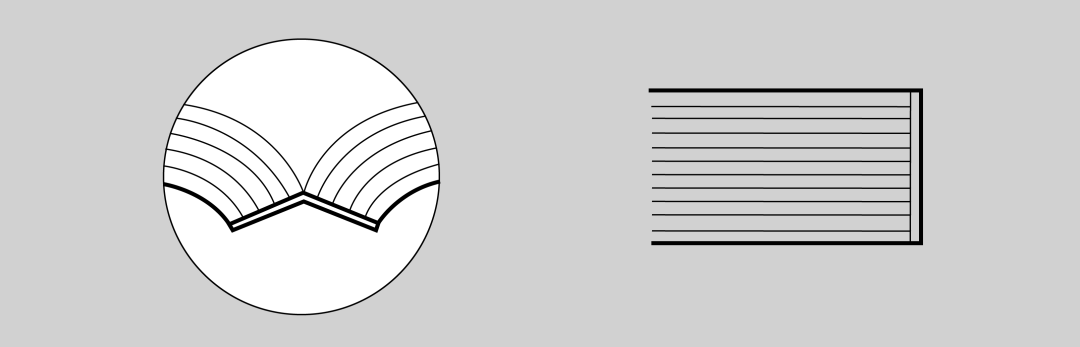

Product features: Adhesive binding, also known as string binding, has a relatively sturdy book core, but due to the large number of binding lines on the back of the book, the flatness is poor. When the book is opened, it can fully display the content of the book.

Advantages and disadvantages: Easy to read, suitable for multi page book binding.

Application equipment: adhesive sewing machine.

Applicable scale: Suitable for product manuals, sample books, picture albums, etc.

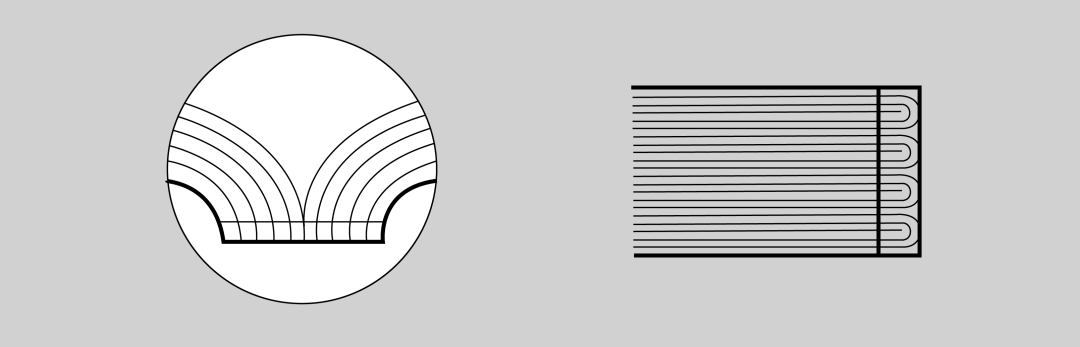

Flat binding

Secure the book with a thread or wire at a distance of 5 millimeters from the edge on one side of the binding opening.

Feature: Unable to fully share, can only be held in hand and flipped through. The more pages there are, the more difficult it is to spread out, so it is necessary to reserve sufficient margin for binding. In order to cover the stitching marks, flat bound books often have the cover directly bonded to the back of the book.

Main use: Extremely thick books must be bound from the side in a flat binding manner.

Wireless adhesive installation

Product features: Wireless binding is the most commonly used binding method, which is the product of condensing loose paper through hot melt adhesive on the spine of the book. Due to its high flatness, most books and periodicals adopt this binding method.

Classification: According to the different types of cover materials, it can be divided into different methods such as European style binding, cardboard adhesive binding, color soft adhesive binding, and color spray adhesive binding.

Equipment used: Gluing machine.

Applicable scale: Suitable for general documents, bidding documents, materials, textbooks, etc.

Attention: After the text is bound, it needs to be trimmed, so important graphics and text should not be placed at the cut.

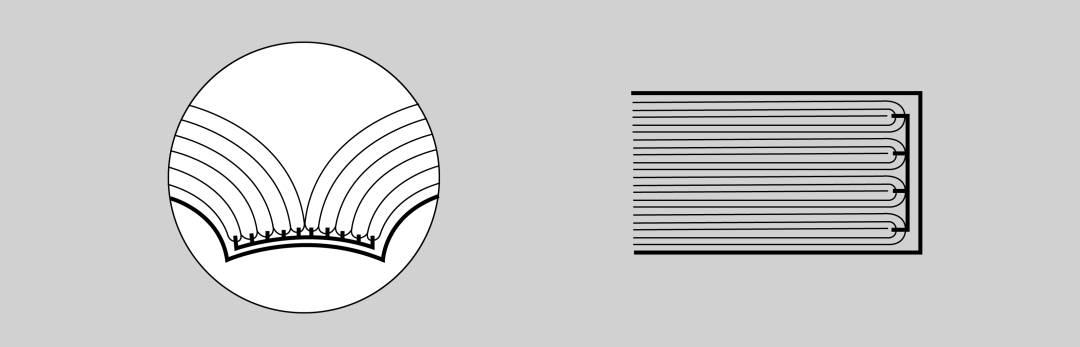

Horseback staple binding

Product features: Horse riding staple binding is a commonly used binding method for books with few pages. The book core can be completely flattened, and the size of the finished product is not limited.

Advantages and disadvantages: Convenient and convenient, easy to browse, and cost-effective.

Equipment used: horse riding nail binding machine, hot laminating machine, paper cutting machine, etc.

Applicable scale: picture albums, picture albums, magazines, journals, brochures, product manuals, introductions, personal materials, business books, etc.